Featured Story:

Quality EDM

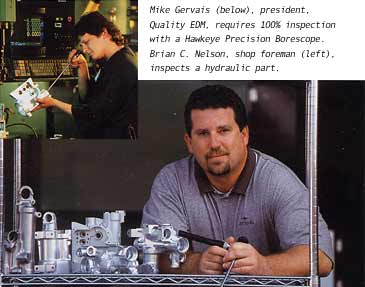

Nobody in the EDM business likes having a customer reject parts because of hidden flaws. Mike Gervais, president of Quality EDM in Anaheim Hills, CA, {manufacturer of hydraulic manifold, hydraulic valve, hydraulic cylinder and other hydraulic component parts} hated it so much that he bought the quality control equipment that his customers used. Today Gervais has a policy of 100% inspection, using Hawkeye® Precision Borescopes. He has not only improved the quality of parts delivered to customers, but has also reduced scrapped parts. "Inspecting carefully during setup minimizes scrap later. This is an important part of cost control for us, since we're working with very expensive parts," says Gervais, who estimates the annual cost savings run to thousands of dollars. Hydraulic repair and hydraulic service facilities also find the Hawkeye borescope a valuable tool to diagnose problems before a major tear down of equipment.